The Importance of Dried Apricot Processing Facilities: A Meeting Point of Quality, Hygiene, and Added Value

Turkey is a leading country that meets a significant portion of the world’s dried apricot production. Especially grown in regions like Malatya, dried apricot is not only an agricultural product but also a strategic asset with high export potential. However, for dried apricots to achieve their deserved value in the global market, field quality alone is not enough. At this point, the dried apricot processing line becomes the key factor in determining the final product quality.

Turkey’s Golden Asset: Dried Apricot

Dried apricot is one of Turkey’s most valuable agricultural products. The production, particularly concentrated in Malatya, is in high demand both in the domestic and international markets. However, the sustainability of this success depends not only on cultivation but also on the quality of dried apricot processing line technologies.

What is a Dried Apricot Processing Line and Why is it Important?

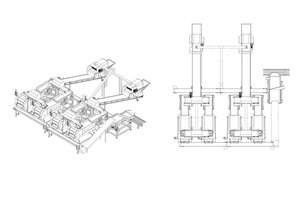

A dried apricot processing line is an integrated system that covers all stages from pre-sorting of harvested apricots to washing, classifying, sizing, and packaging.

Proper planning of this line ensures consistency in product quality, raises hygiene standards, and reduces waste rates.

The Basic Structure of Dried Apricot Production Facilities

A modern dried apricot production facility covers the entire process from raw apricot to the final packaged product. From pre-sorting after harvest to washing, sizing, drying, and packaging—industrial apricot processing machines are used at every stage.

Thanks to these machines:

- Hygiene standards are raised

- Product quality is standardized

- Production capacity increases

- Labor costs are reduced

Stages of the Dried Apricot Washing and Grading Line

1. First Contact: Pre-Sorting and Classification

Harvested apricots are too heterogeneous to be offered directly to consumers. These fruits vary greatly in size, firmness, and surface cleanliness. Therefore, they undergo a pre-sorting process before entering the dried apricot washing and grading line.

At this stage, vibrating screens are used to separate defective and foreign materials and to prepare the product for processing.

2. Washing: The Core of Food Safety

Hygiene is a non-negotiable element of the food industry. A dried apricot washing line ensures the removal of dust, dirt, agricultural residues, and microorganisms from the apricots. This process is crucial not only for consumer health but also for the product’s aesthetic appearance and shelf life.

3. Gentle Handling: Transfer Without Deformation

For transporting washed apricots to the next steps in the processing line, transport systems or soft conveying systems are used. These systems ensure the apricots retain their shape and integrity during transfer to the drying or packaging areas.

4. Grading: The Stage Where Quality and Price Are Defined

One of the most critical factors that determine the market price of dried apricots is their size, color, and physical integrity.

Modern dried apricot grading lines classify the product into different calibers using vibrating screens and, when necessary, optical sorters. This stage directly contributes to the pricing based on quality classes.

5. Automation: Digital Monitoring and Traceability

Advanced dried apricot processing facilities now utilize digital monitoring and automation systems at every stage. This technology makes the production process more efficient, traceable, and less prone to errors. It also provides significant advantages in terms of sustainable production.

Conclusion: More Than Just a Fruit

The dried apricot processing line is not only a tool to support agricultural production, but also a strategic infrastructure that adds value to the national economy.

A well-designed dried apricot processing facility offers the following benefits:

- Improved food safety and hygiene standards

- Standardization in product quality

- Less waste, higher efficiency

- Labor productivity and time savings

- Increased competitiveness in the international market

Let us not forget: the value of a dried apricot is not just in its packaging, but in the precision of its processing.

Facilities that combine traditional methods with modern technology don’t just dry apricots—they transform them into a high-quality global brand.

Frequently Asked Questions (FAQ)

✅ How much does it cost to set up a dried apricot processing line?

Setup costs vary depending on capacity and technology level. You can use our ROI calculator for detailed information.

✅ What standards are required for exporting dried apricots?

Food safety certifications such as BRC, ISO 22000, and HACCP are essential for export compliance.